In wenigen Schritten zur idealen Reinigungsanlage

Finden Sie Ihre ideale Reinigungsanlage – schnell und unkompliziert!

Entdecken Sie in nur wenigen Schritten die perfekte Reinigungsanlage für Ihre Anwendung. Geben Sie Ihre Anforderungen ein und erhalten Sie maßgeschneiderte Lösungen – sichern Sie sich jetzt Ihr kostenloses Infopaket!

Der Spezialist für Ihre Anwendungen

Als einer der führenden Anbieter für industrielle Reinigungsanlagen sind wir der Spezialist für individuelle Lösungen. Wir kennen die unterschiedlichen Herausforderungen und Ansprüche der Reinigung in den Branchen Fahrzeugtechnik, Bahn, Maschinenbau, Härterei, Gießerei und vielen weiteren.

High Purity

In der Halbleiter‑, Optik‑, Medizin- und Präzisionstechnik entscheidet absolute Sauberkeit über Performance und Verlässlichkeit. Wenn Bauteile mit komplexen Geometrien partikulär bis 0,5 μm und rückstandsfrei auf molekularer Ebene gereinigt werden müssen, braucht es mehr als Standardtechnik: Wir bei BvL verbinden Prozess‑ und Materialverständnis mit passgenauer Anlagentechnikund richten den Reinigungsprozess exakt auf Ihre Anforderungen aus.

Haushaltsgeräte

Unsere Reinigungsanlage integriert sich optimal in Ihren Produktionsprozess: Ihre betriebsinternen Abläufe bestimmen die Auslegung der Anlage. In der Herstellung von Haushaltsgeräten und Kochgeschirr bestimmen hohe Durchsätze und durchlaufende Fördertechnik häufig den Produktionsablauf, die wir mit unserer BvL Reinigungsanlage aufgreifen.

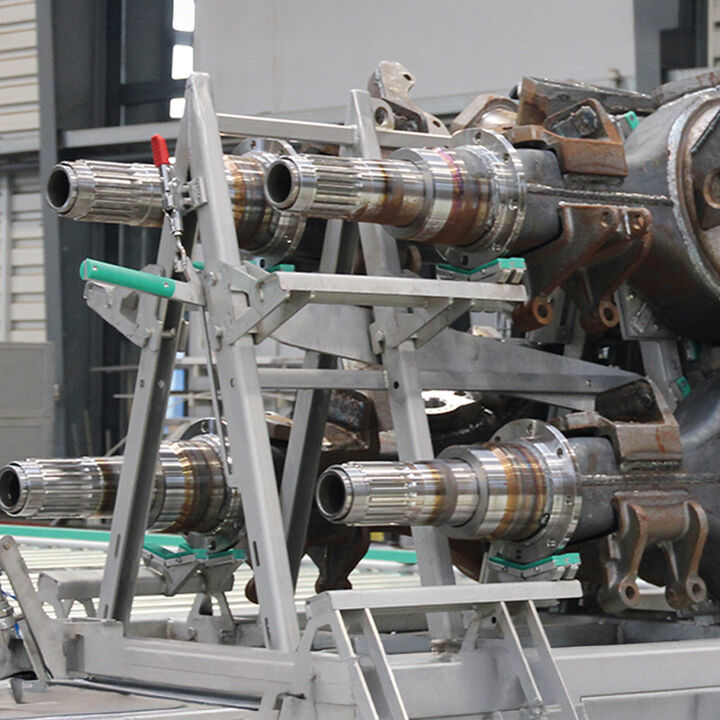

Schienenverkehr

Die BvL Oberflächentechnik GmbH verfügt über tiefgreifendes Fachwissen im Bereich der Anlagenauslegung für Extremanwendungen. Sowohl in der Produktion, als auch in der Instandhaltung ist die Sauberkeit der Teile wichtiges Qualitätsmerkmal für die Weiterverarbeitung.

Defence

Zuverlässigkeit, Sicherheit und Funktionalität – das sind unverzichtbare Anforderungen an militärische Systeme und ihre Komponenten. Mit unseren industriellen Reinigungsanlagen erfüllen Sie die hohen Standards der Verteidigungsindustrie: von der Produktion über die Wartung bis zur Dekontamination. Ob Getriebeteile, Hydrauliksysteme oder Waffenmodule – wir bieten maßgeschneiderte Lösungen für Ihre Sauberkeitsanforderungen.

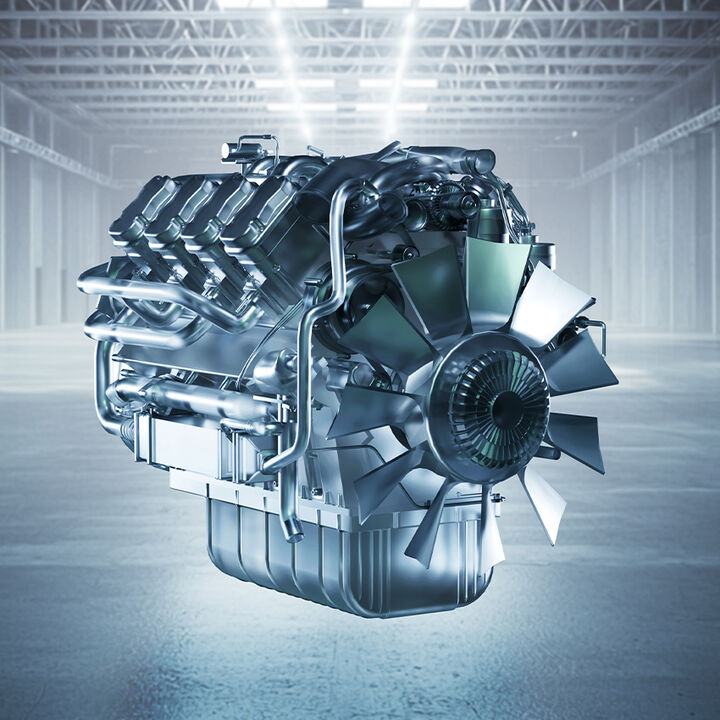

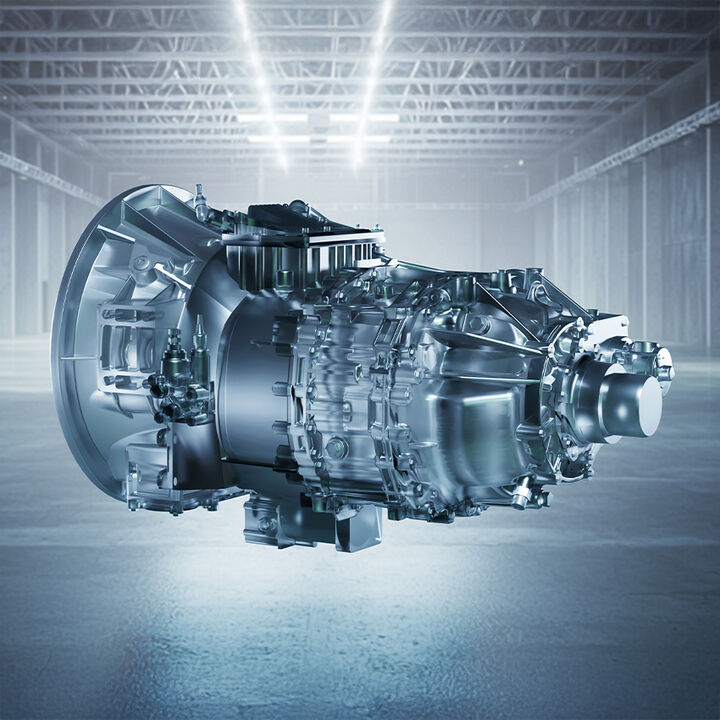

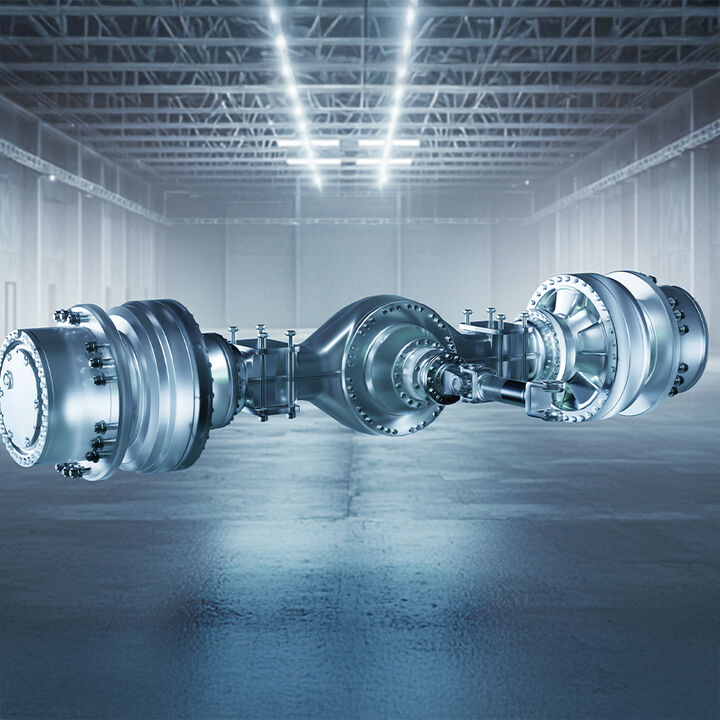

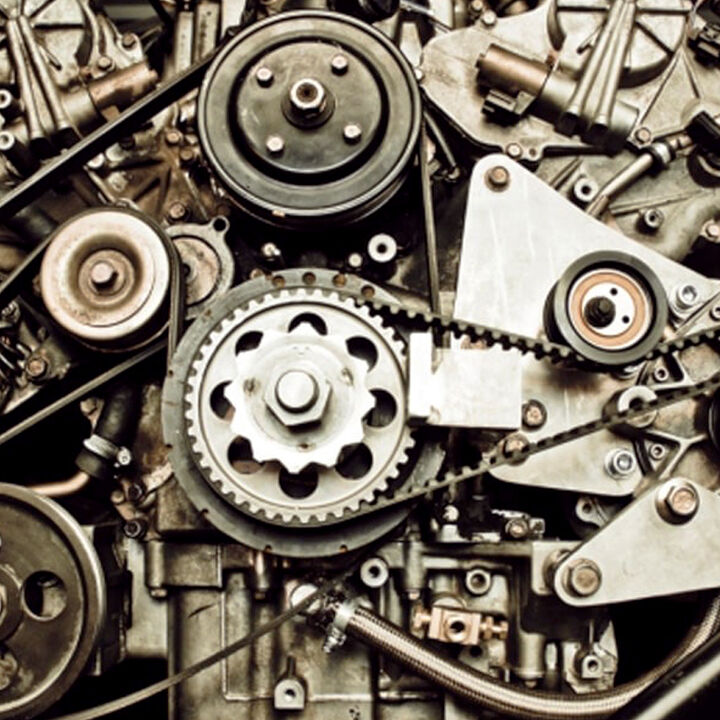

Fahrzeugtechnik

Höchste technische Sauberkeit rund um den Bereich Getriebe und Powertrain für die Automobil- und Nutzfahrzeugindustrie, sowie in der Landtechnik: denn die Anforderungen an die technische Sauberkeit steigen mit jeder neuen Generation im Fahrzeugbau.

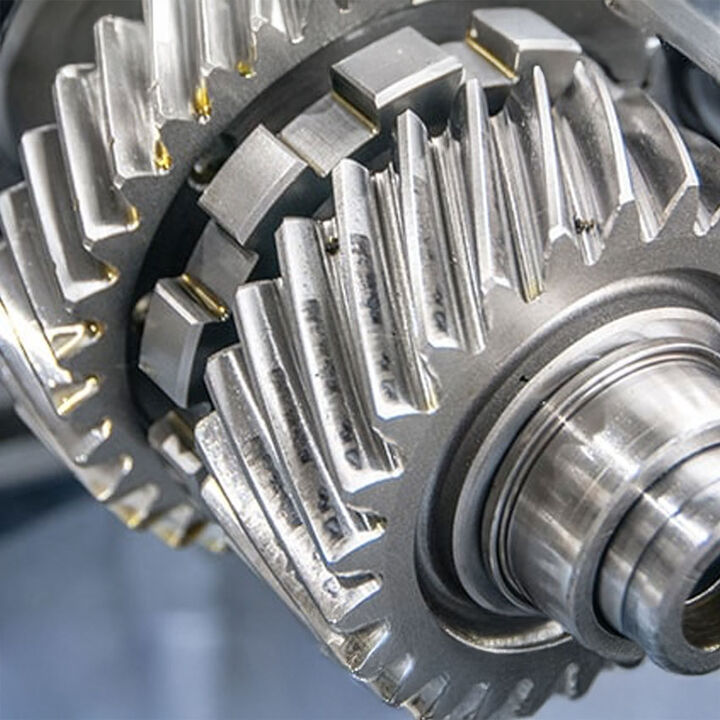

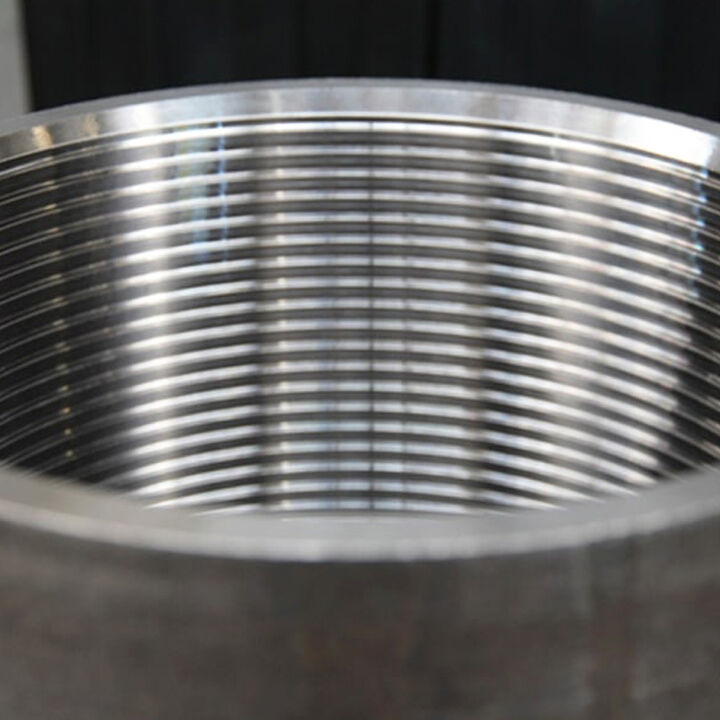

Härterei

Wärmebehandlungsprozesse erfordern rückstandslose, fleckenfreie Bauteilsauberkeit, denn Rückstände verursachen fehlerhafte Prozessergebnisse. Ein gleichmäßiger Schichtaufbau in der Weiterbearbeitung kann nur erfolgen, wenn die Bauteile ausnahmslos sauber sind.

Weitere Branchen

In nahezu jeder Branche gibt es die Notwendigkeit der Sauberkeit von Bauteilen – insbesondere bei technisch anspruchsvollen Produkten oder Bearbeitungsprozessen. Egal in welchem Anwendungsbereich zuverlässige Reinigungsanlagen benötigt werden, wir entwickeln passend zugeschnittene Lösungen flexibel nach Ihren Sauberkeitsanforderungen.

Wir finden die optimale Lösung für Ihre Anwendung

Sie wollen Bauteile testen lassen, ein Angebot anfordern oder mehr über unsere Reinigungsanlagen erfahren?

Jetzt unverbindlich Kontakt aufnehmen oder Beratungsgespräch buchen.