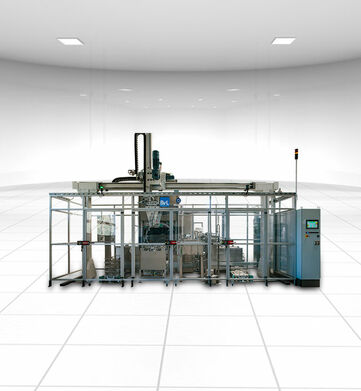

Niagara basket washing systems

Cleaning processes combined in one chamber

The Niagara product series from BvL is suitable for cleaning single parts, bulk material and set/basket goods. It comprises all front-loading basket washing systems offered by BvL.

The holding system turns or swivels in the chamber and securely holds the parts in the basket or on the workpiece carrier at the same time. This rotational movement and treatment using a spray process or combined spray/flood process ensures the efficient, all-round powerful cleaning of the parts – even those with complex geometries or parts with recesses or cavities.

All process steps such as cleaning, rinsing and drying are carried out in one space-saving chamber. Each system can be integrated into the specific production flow using a diverse range of automated systems – for precise cleanliness and short processing times.

- The holding fixture rotates or swivels around the horizontal axis

- All-round cleaning with spray or spray/flood cleaning using a special nozzle frame

- All processing steps in one chamber: cleaning, rinsing, drying

- Highest level of cleanliness due to optional ultrasound cleaning and various different drying systems

- A variable system for many different dimensions and loads