| Cleaning system: | spray cleaning with flat spray nozzles |

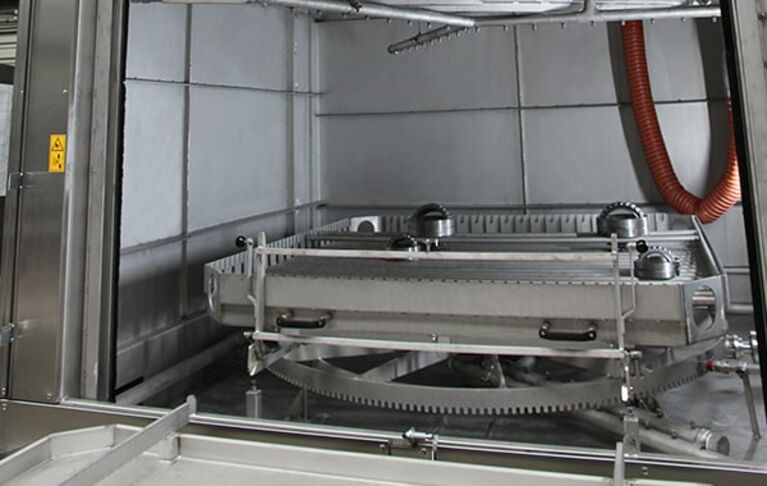

| Functional principle: | rotating parts holder with a static nozzle system for all-round cleaning of the parts |

| Tank systems: | separately heated single-tank or multi-tank systems with large volumes to extend the service life of the medium |

| Loading: | front loading using the stationary front table: removable loading carriage with grate |

| Housing: | low-maintenance stainless steel for a perfect look |

| Tank insulation: | stainless steel for high energy efficiency |

| Control and operation: | Siemens Simatic with user-friendly Siemens touch panel |

| Bath monitoring: | Libelle Fluid Control for the best quality processing water |

| Filter system: | removable basket filter removes large particles of dust during the flow back of the cleaning/rinsing process |

Intelligent cleaning with BvL apps and digital networking. Transparent process information for predictive system diagnostics and maintenance: efficient and automatic.

Versions- loading from both sides or synchronized flow possible

- RD variant for particularly difficult parts: Nozzle frame rotates around the stationary parts holder

Auf einen Blick

- high cleaning performance even for persistent contaminations

- for applications with increased loads

- for applications with high contamination

Technology in detail

Cleaning technology

Cleaning technology

- the turntable revolves around the vertical axis

- all-round component cleaning through special U-shaped nozzle system

- a separate nozzle frame for each tank reduces mixing

- nozzles and nozzle frames can be adapted to the component

- usable dimensions, load capacities and pump capacities can be adapted

Processing steps

Processing steps

The processing steps are carried out in a chamber:

- spray washing

- spray rinsing (for multiple tank system)

- rinsing with demineralized water (optional)

- circulating air drying (optional)

Options and supplements

Options and supplements

- Nevada drying systems

- handling systems: loading carriage, stationary table with cross moving, bridge loader and automation

- bath maintenance options (e.g. filtration systems, oil separator)

- process reliability: Libelle Cleaner Control, Libelle Oil Control, Libelle Data Control, remote diagnosis

- Cascade guiding for multiple tank systems

- floor drip tray

- other system components