Continuous stress, long service times and the large distances covered by the trains leave their marks and often also cause damage to wheel bearings. Cleaning and removing grease and oils is absolutely essential for subsequent crack testing and servicing tasks.

Different forms of wheel bearings and their complex geometries complicate the cleaning process. It needs to be able to handle heavy grease deposits and clean hard-to-reach interior spaces.

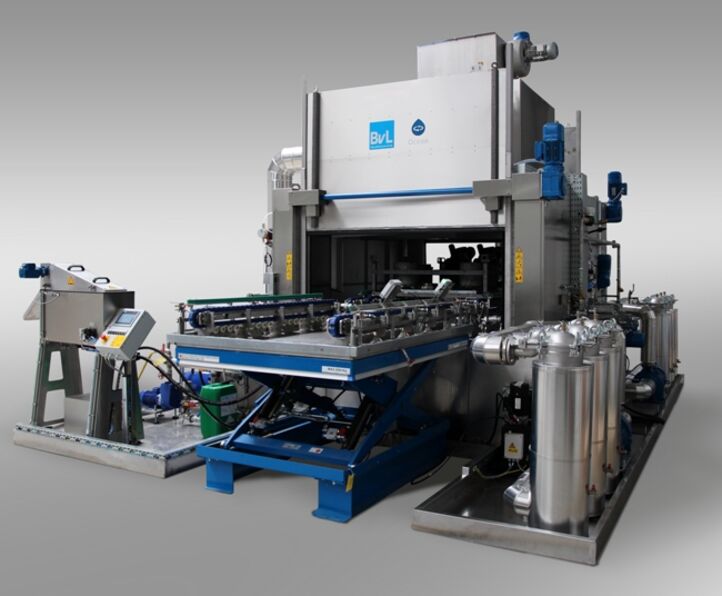

The cleaning systems must be able to satisfy the corresponding requirements. The OceanRW turntable system and the YukonDA conveyor system are able to handle the challenges posed by wheel bearings and bearing housings, irrespective of whether they are cylindrical roller bearings, spherical roller bearings or other types of bearings.

- Optimal handling and shorter operating times

- Bearings can be directly placed on parts holders

- Special nozzle system for all-around, intensive spray cleaning using a spray process

- Automatic lifting gate

- Also possible to use as a conveyor system in cycle operation

- High throughput

- Extremely low handling effort

- Individual conveyor options

- Specially arranged spray nozzles clean hard-to-reach interior spaces