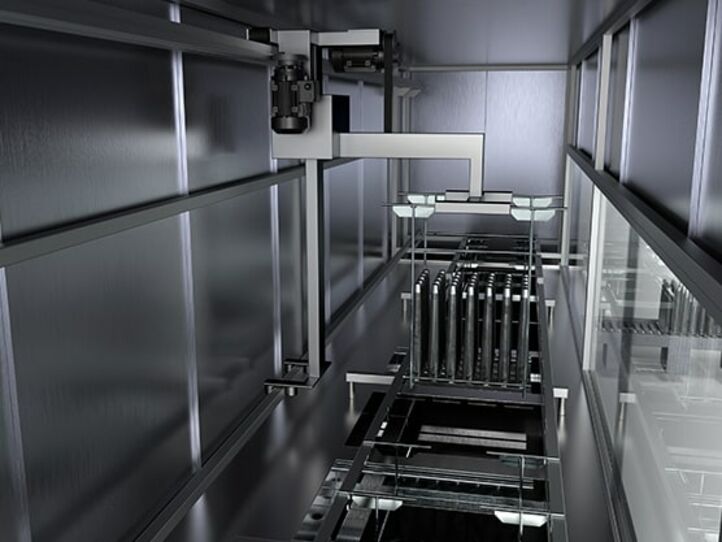

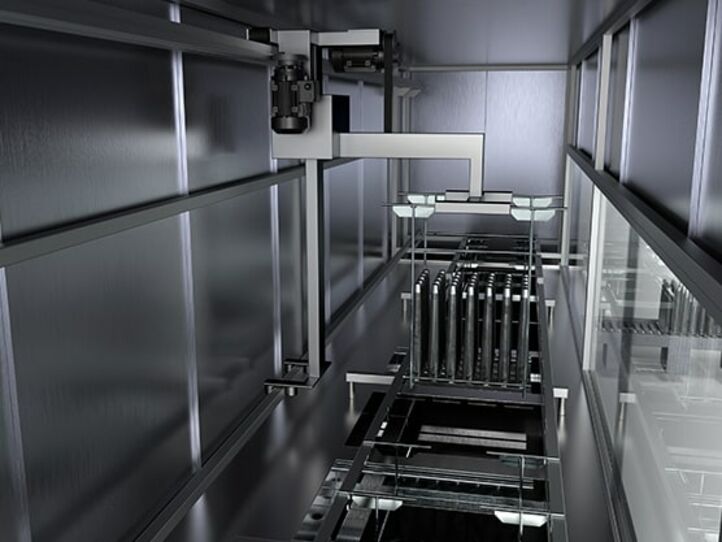

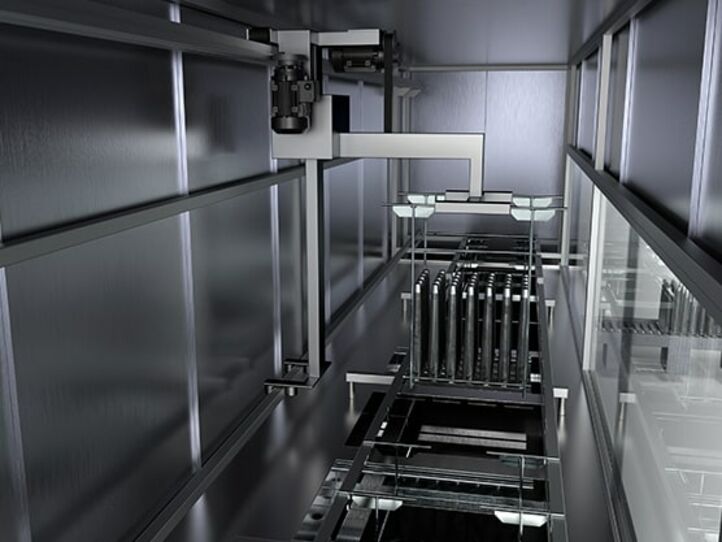

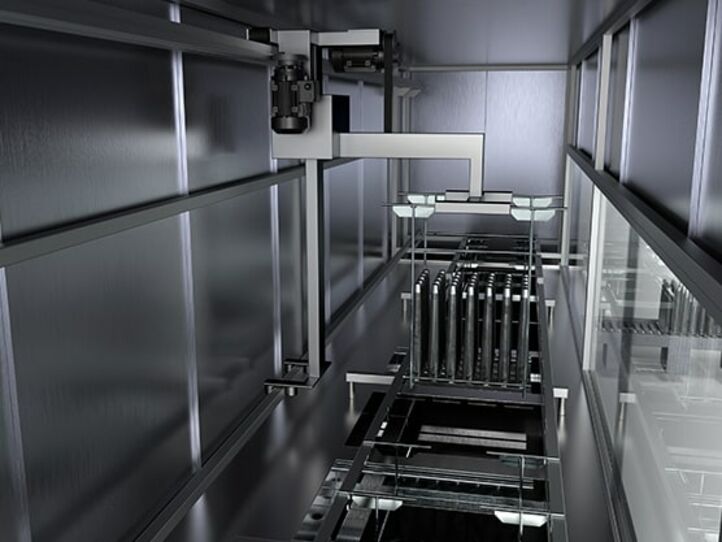

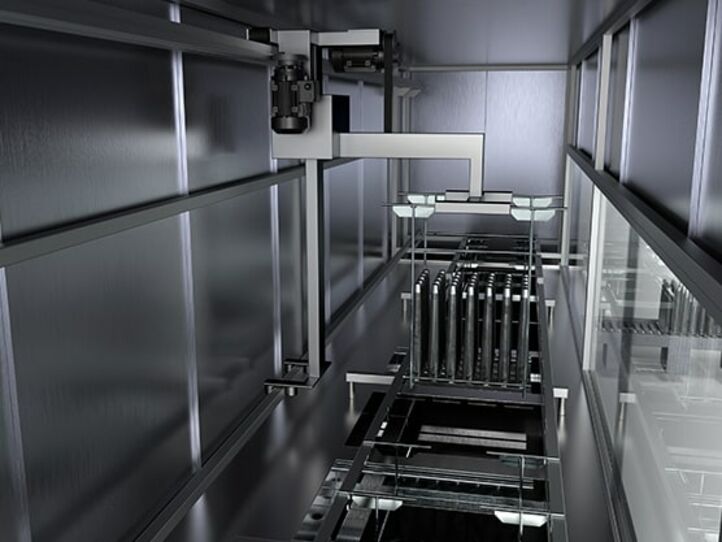

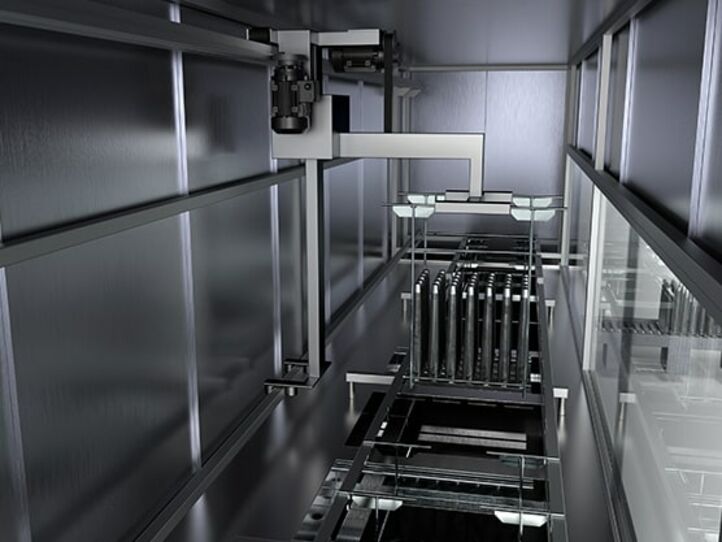

Atlantic multi-chamber immersion cleaning system delivers precision cleaning tailored exactly to requirements

Bespoke precision cleaning: BvL Oberflächentechnik GmbH presents the AtlanticTR, its new immersion cleaning system, capable of handling the most stringent technical cleanliness requirements

Advanced technologies demand greater cleanliness, because the more functions a component performs, the greater the likelihood they will be impaired by contamination. This calls for precision cleaning – an ideal job for the new AtlanticTR immersion cleaning system from BvL Oberflächentechnik.

Optimizing material flow through integration into the production process

With the AtlanticTR, customers benefit in particular from the individually scalable size of the system. The immersion cleaning system can handle ultra-small fine parts with complex geometries and high throughput rates all the way through to large components with high batch weights. The multi-chamber immersion cleaning system can also be combined with other water-based cleaning systems from BvL, paving the way for optimum alignment with the entire production process. Not only does BvL Oberflächentechnik offer flexible feed and removal systems to fit the cleaning system that use a range of conveyor technologies, the loading and discharge stations for loading and unloading can also be positioned in various ways, both at the sides and at the front. Parts cleaning can thus be tailored exactly to the specific production process, the material flow, and the available space.

Modular, multi-stage cleaning processes

With its cleaning technology, the AtlanticTR offers a precisely coordinated combination of immersion/spraying, injection spraying, rotation, oscillation, and ultrasound. The different cleaning processes are combined in a multi-stage system and can be used in a modular fashion. Flexible product movement in the cleaning, rinsing, and drying modules further enhances cleanliness. Vertical oscillation as well as swiveling and rotating movements can be realized. The separation of the cleaning agents also makes it possible to combine the various processes in the individual dip tanks to achieve an optimum cleaning process. Flexibility is further enhanced by the automatic transport system using a gantry transfer unit, which can be programmed in any sequence. Finally, drying is integrated into the cleaning system and can be performed as circulating air, vacuum, or infrared drying.

Areas of application

With this equipment, the AtlanticTR is suitable for particular and filmic cleanliness in precision cleaning: Whether it is deployed in electromobility for the automotive sector, hydraulics and pneumatics, optics, electronics, aerospace, the coating industry, watches and jewelry, or high-purity applications, it can meet its highest cleanliness and capacity requirements by immersion cleaning and immersion degreasing.

Quality assurance and process reliability

The Smart Cleaning apps offer even more process reliability. They make the BvL cleaning systems smart by displaying any process changes on the control panel immediately. Sub-processes regulate themselves automatically, and operators no longer need to intervene in these intelligent processes. Anyone who wants to see for themselves exactly what the AtlanticTR multi-chamber immersion cleaning system can do can carry out their own cleaning tests at BvL’s in-house Technology Center using original components.