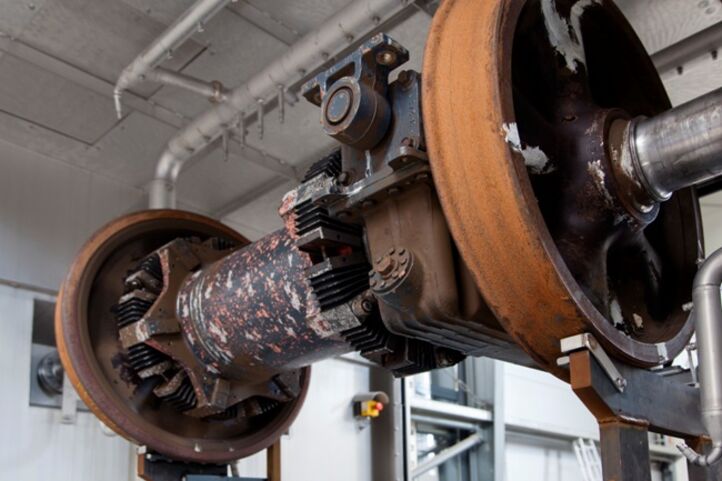

After trains have been used intensively for many years, the wheel sets also collect a huge amount of soiling in the form of hard encrustations, grease, brake dust, etc. It is also often necessary to remove old and sometimes multiple layers of paint to allow the completion of crack testing or repainting tasks.

Another challenge faced in the cleaning of wheel sets are their heavy weights of up to multiple tonnes. In addition, drive wheel sets and running wheel sets need to be handled differently.

In order to satisfy the cleaning requirements, a large parts system with sufficient space and adapted technology is required – such as our PacificER/TA systems or our Geyser system.

The PacificER is a large volume spray cleaning system. The wheel sets are rotated and cleaned using a nozzle system adapted to their contours. Loading is carried out automatically and at floor level. The PacificTA has a special frame system for the targeted cleaning of hard-to-reach spaces on various different wheel sets.

The Geyser uses a robot system and the power of a high-pressure water jet for cleaning and paint stripping. Depending on level of soiling, cleanliness requirements and paint layers, the pressure range varies from 100 to 3,000 bar.

- Automatic feeding and discharge

- Individual adaptation of the nozzles to the wheel set

- Continuous feeding

- Maximum flexibility and precision thanks to robot technology

- No thermal or mechanical strain on the surface

- Optionally changeable tools, nozzles and lances